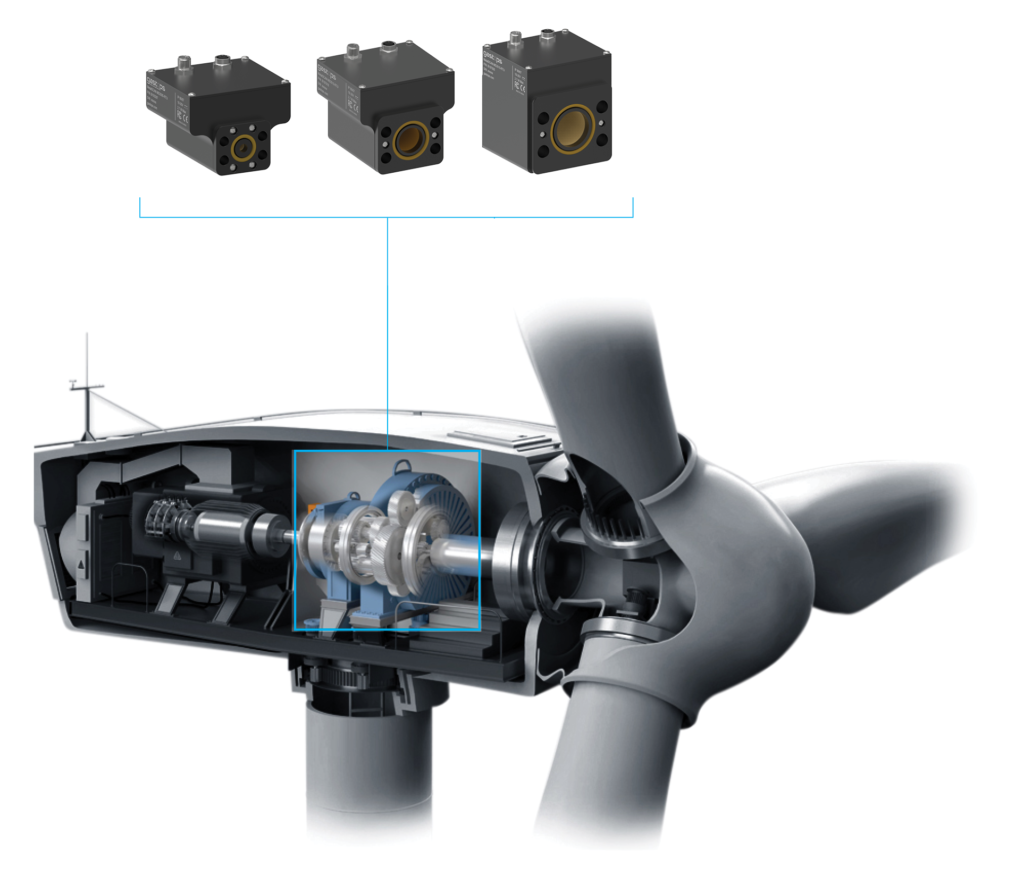

MetalSCAN is a full-flow, non-obstructive, online debris detection system designed to detect the onset of surface fatigue of bearings and gears. It is used as a condition monitoring device to determine the condition of the gearbox. The gearbox is thereby continuously monitored, allowing the operator to track the progressive deterioration of any damaged bearings or gears in real time.

The sensor is installed in the lubrication oil lines, before the oil filter, with standard flanges and fittings adapted to the turbine configuration.

Several convenient data communication options are available, including direct connection to the turbine controller, an existing CMS system, or the local area network, or by fully standalone cellular network connection, to suit specific needs.

Back to News & Resources

Back to News & Resources