Extending

equipment life

and ensuring

reliability

Gastops performs laboratory testing services for some of the biggest organizations in the aerospace, defence and energy and industrial sectors. Gastops is a recognized leader in laboratory analysis services for condition monitoring of fluid, filter, and chip debris in aerospace engines and transmissions, aeroderivative turbines, ship propulsion systems, and other oil-wetted industrial equipment.

Gastops is a licensed provider of TestOIL services and partners with Pratt & Whitney Canada to deliver their Oil Analysis Technology attesting to our excellent service standards and laboratory capabilities trusted by the industry’s biggest names.

Our laboratory team is composed of maintenance engineers (commercial and military), professional engineers, data scientists, and lubrication specialists. We combine in-depth understanding of our customers’ operations with carefully selected test packages that meet the requirements of various manufacturer maintenance programs. With Gastops, our customers can accurately, efficiently, and cost effectively diagnose the condition of these critical assets.

Filter Debris

Analysis

Filters capture the majority of wear debris in lubricating oil. Gastops is an industry leader in filter debris analysis, having pioneered the technology with the introduction of FilterCHECK in the 2000’s and contributing to the development of multiple ASTM standards. Gastops continues to offer this capability within our lab services as part of our comprehensive condition-based maintenance (CBM) solutions. Filter debris analysis is a proven and effective method of proactively monitoring gear and rolling element bearing damage modes.

Oil, Coolant, and Fuel Analysis

Fluid analysis of oil, coolant, and fuel is a commonly used condition monitoring technique used to evaluate fine wear debris, fluid condition, and fluid contamination.

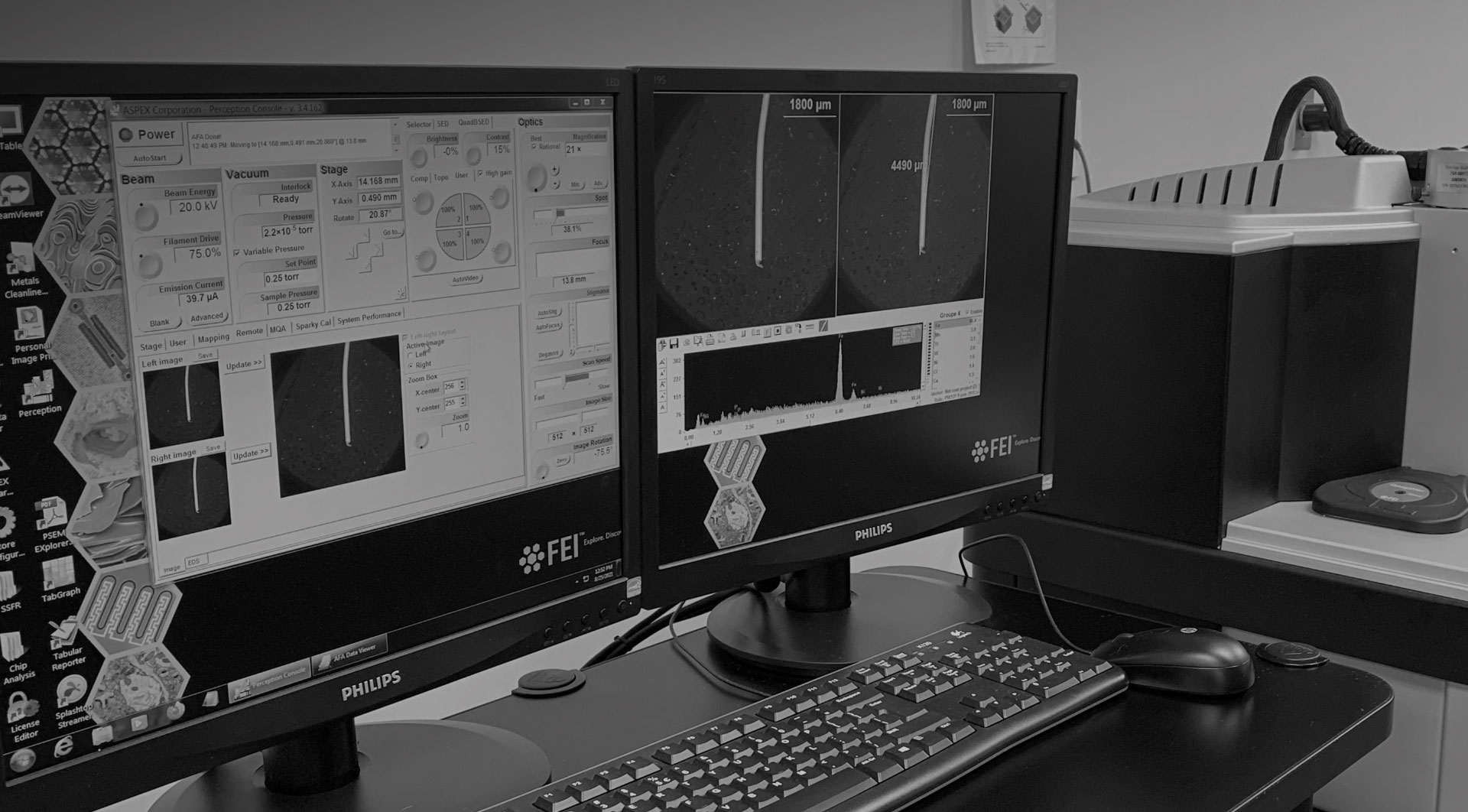

Laboratory Chip Debris Analysis

Chip detectors typically capture 15% of wear debris from gears and bearings. When chip lights occur, there is often a requirement to identify the material of the chips collected, along with physical measurements and appearance. Gastops SEM-EDX provides elemental composition analysis of chips using our extensive material library of common alloys and materials used within engines and gearboxes.

Advanced Oil Fines Analysis

Gastops is an exclusive partner to Pratt and Whitney Canada (P&WC) in the provision of their Oil Analysis Technology service, providing proactive and preventive maintenance without intrusive inspection for a growing list of PWC engine models. This program is a natural complement to Gastops’ MetalSCAN oil debris sensors and ChipCHECK debris analyzer products in detecting possible events up to hundreds of hours in advance, including carbon seal deterioration.