ALWAYS-ON, ALWAYS VIGILANT. EQUIPMENT CONDITION MONITORED BY OUR EXPERTS.

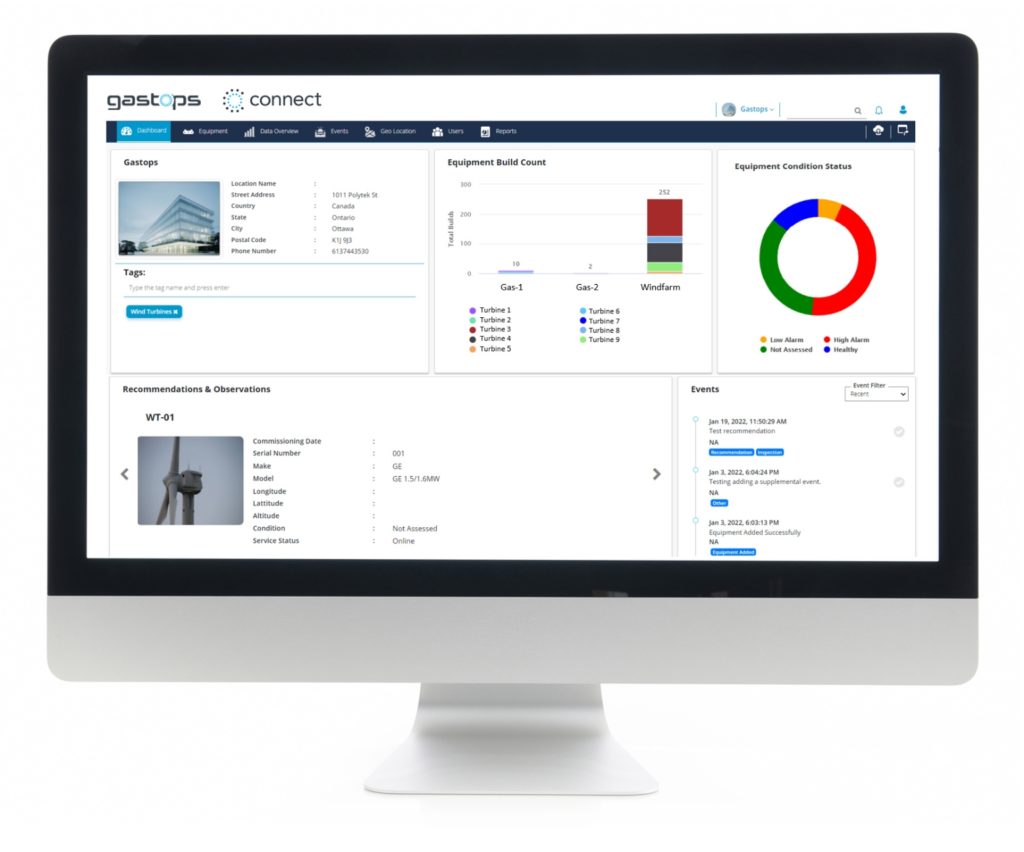

Gastops Connect collects, processes, and analyzes data from MetalSCAN sensors, combines it with your equipment controller data and third-party data to create a comprehensive, real-time view of equipment condition accessible through any web browser device. It also provides an aggregated view across multiple sites for better analysis.

Equipment operators, asset managers and maintenance professionals gain access to instant notification of changes in equipment condition, and visibility into the health of equipment located anywhere in the world.

Real-time oil debris monitoring. Anytime. Anywhere.

The Fast Facts about Gastops Connect

- Cloud-based condition monitoring portal for easy access

- Monitoring and analytics platform suitable for all types of oil wetted equipment applications

- Tailored watchlists, dashboards and reports allowing users to focus on critical assets

- Personalized SMS, email and web-based warnings, alarms, and event notifications

- Configurable views including equipment cross-comparisons by type, location and more

- Integrated REST API and SFPT server for easy data sharing with 3rd-party systems

- Data import and export in several industry-standard formats along with direct integration into MetalSCAN Monitor software

Gastops Equipment Condition Analytics (ECA) Services

With over 40 years of equipment condition data analysis, intelligence, and technical expertise in manufacturing world-class instrumentation, our team of Equipment Condition Analytics experts is well positioned to provide unparalleled advisory and monitoring services. This key capability is available to users registered for the premium level monitoring service.

Gastops Connect Condition Monitoring Services

Gastops Connect enables you to gain better access and enhance the monitoring of your critical asset. Instantly observe your equipment’s health, damage indicators and Remaining Useful Life (RUL) online while accessing an elite team of diagnostic specialists giving you the power to effectively plan maintenance and avoid costly component replacements.

Connect is a multi-tiered subscription service suited for all types of operators including self-performers and those requiring additional technical expertise.

Premium Condition Monitoring Service – Turnkey monitoring service including access to Gastops’ ECA team and monthly fleet status reports

Basic Condition Monitoring Service – Secure data hosting and management service provided by Gastops

connect

connect